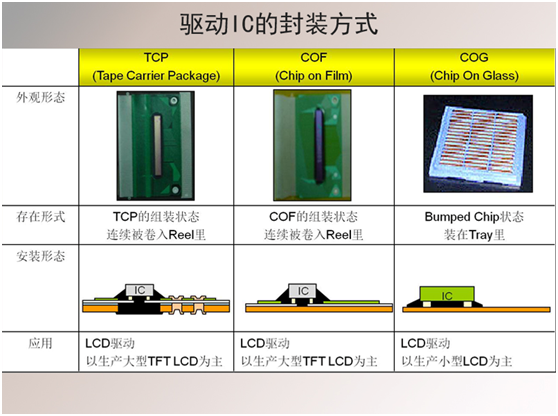

In the circuit components of the LCD liquid crystal screen, in addition to the resistor R, the capacitor C, the inductor L, etc., the most important component is the driver IC, that is, the integrated circuit chip. Commonly used driver ICs include power supply ICs, timing control ICs, data line driver ICs, scan line driver ICs, low-dropout linear stabilizer ICs, and EEPROMs. Hongcai Technology has sorted out the current conventional packaging methods in the industry to introduce the packaging methods of driver ICs. In the LCD liquid crystal display, the packaging methods of the driver IC include TCP, COF, COG and so on.

The driver IC in COG is crimped on the glass in the form of a bare chip. In TCP and COF, the driver IC is crimped on the TAB strip and then protected with epoxy resin. The base material of the TAB tape is polyamide tape. The adhesive is coated on the base material and then pasted with copper foil. The wiring pattern on the copper foil is formed by etching according to the BUMP definition of the driver IC.

TCP encapsulation is a technology in which the BUMP of the driver IC and the Cu pins on the polyimide tape is joined by eutectic welding and protected by epoxy resin encapsulation. The TCP is composed of three layers of materials. If the TCP needs to be bent, two more slits must be added to the TCP. As a result, the total length increases, and the cost also increases.

COF is a die-soft film packaging technology, which is composed of two materials: a polyimide layer and a copper foil layer. The thickness of COF is relatively thin, and it can be bent directly when it encounters a place that needs to be bent in the structural design. The structure of COF is similar to the FPC of a single-layer board. Except for the different glue used, the thickness and bendability of COF are better than that of FPC. Because COF is light, thin, and short, has high packaging density, and is mostly a two-layer film structure, it is crimped on the same plane as the display, PCB, and IC components.

In summary, the mainstream driver chip packaging methods have their own advantages and disadvantages. However, the current LCD liquid crystal display on the market still uses COG as the main driver IC packaging method.

The above is a brief introduction to the packaging method of the LCD driver IC. I hope that you will understand the knowledge and principles of LCD LCD screens.