- Use only a dry, soft cloth to clean the LCD screen. Do not use liquid or chemical cleansers.

- If the liquid crystal solution gets on your hands, wash them thoroughly with soap and water. If the liquid crystal solution gets into your eyes, flush them immediately with water. If discomfort or vision problems remain after a thorough flushing, see a doctor immediately.

- Do not press too hard on the LCD screen or subject it to heavy impacts.

- Do not use a pointy or sharp object, such as a pen or your fingernail, to operate the LCD screen.

- If the LCD screen chips or cracks, do not touch or attempt to remove the broken pieces; contact Epson for support.

- Do not subject your product to sudden changes in temperature or humidity; this may cause condensation to develop inside the LCD screen and degrade its performance.

- The LCD screen may contain a few small bright or dark spots, and may display uneven brightness. These are normal and do not indicate that the screen is damaged in any way.

Precautions for storage

When TFT displays will be stored as spare parts for a long period of time, the following precautions need to be taken.

(1). Store them in a dark place. Do not expose the modules to sunlight or fluorescent lamps. Maintain a temperature of 5°C to 35°C at normal humidity.

(2). The surface of the polariser should not come into contact with any other objects. It is recommended that they are packed for delivery

Installation precautions

(1). The TFT LCD module must be installed using an anti-static environment.

(2). Consideration should be given to the mounting structure so that no uneven forces (e.g. twisting stresses) are applied to the TFT display module. The situation in which the TFT display is mounted should be strong enough so that external forces are not transmitted directly to the module.

(3). Please apply a layer of transparent protection sheet to the surface to protect the polarising lens. The transparent protection sheet should be strong enough to resist external forces.

(4). Radial construction should be used to meet temperature specifications.

(5). Acetic acid type and chlorine type materials used for cover shells are not described as the former produces corrosive gases that attack the polariser at high temperatures and the latter causes circuit breakage through electrochemical reactions.

(6). Do not touch, push or wipe the exposed polarizer with glass, tweezers or anything harder than an HB pencil lead. Do not wipe with chemically treated dusty clothing. Do not touch the surface of the polarizer with bare hands or greasy cloths.

(7). Wipe off saliva or water droplets as soon as possible; their prolonged contact with the polarizer can cause distortion and fading.

(8). Do not open the housing as the internal circuitry is not strong enough.

Handling Precautions

(1). Spike noise causes misoperation of the circuit. It should be below the following voltage: V = ±200mV (overvoltage and undervoltage).

(2). Reaction time depends on temperature. (At lower temperatures it will become longer.)

(3). Brightness depends on temperature. (At lower temperatures it gets lower) and at lower temperatures the reaction time (the time it takes for the brightness to stabilise after switching on) becomes longer.

(4). Beware of condensation during sudden temperature changes. Condensation can damage the polariser or electrical contact parts. Smearing or spotting can occur after fading.

(5). When displaying a fixed pattern for a long time, residual images may appear.

(6). TFT LCDs have high frequency circuitry. The system manufacturer should provide adequate suppression of electromagnetic interference. Grounding and shielding methods may be important to minimise interference.

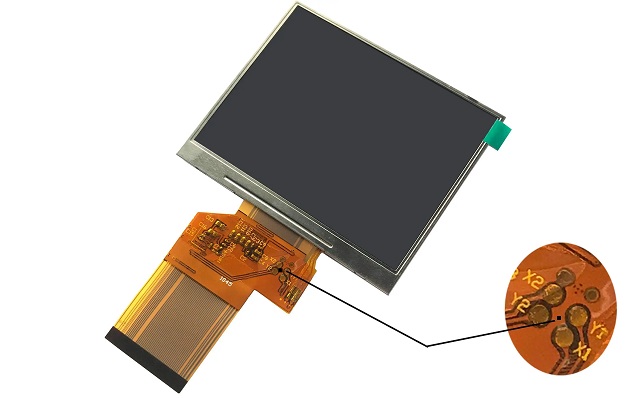

Electrostatic discharge control

TFT displays are composed of electronic circuitry and electrostatic discharge can cause damage. Operators must wear electrostatic hand rings and be earthed. Do not touch the pins on the interface directly.

Precautionary measures for bright light exposure

Exposure to strong light can cause deterioration of the polarizer and colour filter.

Precautions for handling protective films

(1). When the protective film is removed, static electricity will be generated between the film and the polarizer. This should be peeled slowly and carefully by electrical grounding and ion blowing equipment or by the person under these conditions

(2). The protective film will have a small amount of adhesive adhering to the polarizer. It tends to remain on the polarizer. Please peel off the protective film carefully and do not rub it against the polarizer.

(3). When the module with the protective film is stored for a long period of time, a very small amount of adhesive may remain on the polarizer after the protective film has been removed.

Other precautions

(1). Avoid applying excessive shocks to the TFT display or making any changes or modifications to the module.

(2). Do not leave additional holes in the printed circuit board, modify its shape or replace parts of the TFT module.

(3). Do not disassemble the TFT display.

(4). Do not exceed the absolute maximum rating during operational use.

(5). Do not drop, bend or distort the TFT display.

(6). Soldering: I / O terminals only.

(7). Storage: Store in anti-static container packaging and in a clean environment.

(8). Notice to customers: Please take care when using the modules that no tape is applied to the module parts. This is because the tape may damage the functional structure of the parts when it is removed and cause electrical abnormalities in the LCD.

If the application of adhesive tape to a component is unavoidable due to mechanical constraints, the following methods are available to avoid such anomalies.

(7-1) The adhesive force of the applied tape must not be greater than that of [3M-600] tape.

(7-2) There should be no tearing of the tape after it has been applied.

(7-3) When it is necessary to remove the tape, it is recommended that the tape be removed with the aid of heat.